Screen printing Munich - T-shirt & Textile printing

In our screen printing shop we carefully print individually selected textiles for you by hand and automated on the best technical screen printing machines. We use only the highest quality inks and selected materials to ensure the highest quality standards. Fine line and perfect color reproduction distinguish the printing method - screen printing directly from the in house screen printing workshop in the heart of Munich.

All-round service with screen printing - textile printing - textile finishing - embroidery - digital printing in the heart of Munich

In addition to the screen printing process, we of course offer you alternatives and other finishing techniques for further processing. Depending on the required quantities and application, we also offer digital printing, transfer printing and embroidery in addition to screen printing. If it is about the textile itself, we accompany you completely through a production of the desired textiles. We will be happy to advise you on the best color, fabric such as cotton or polyester to use for your textile. Cut and quality we agree together in Munich.

SCREEN PRINTING EXAMPLES FROM THE SCREEN PRINTING ARSONISTS

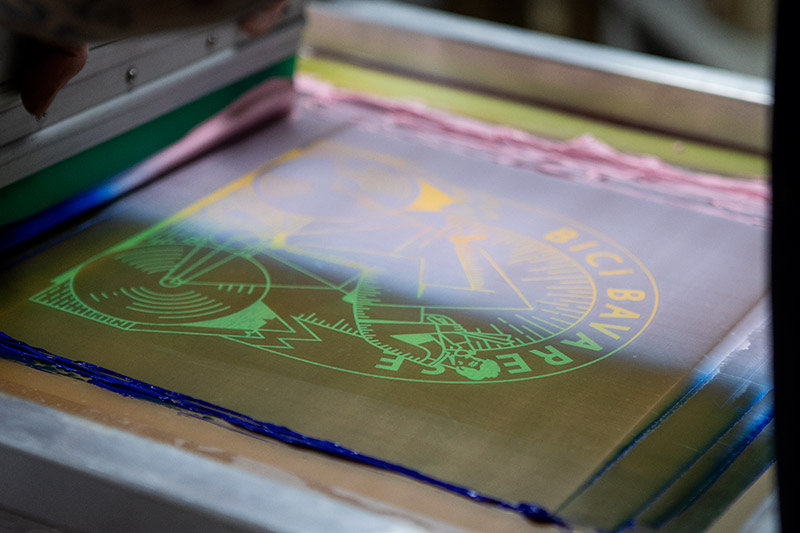

We can print up to 6 colors in screen printing. In this example you can see the structure of a screen print on a Fairtrade textile from Stanley Stella.

In combination - 3D screen printing with multicolor direct screen printing. Screen printing of course also works on heavy fabrics.

In this example, a 6-color screen print with additional puff base was printed. Details in the design can be highlighted particularly well by the three-dimensional print.

Here we have printed a two-color screenprint on a black textile of Stanley Stella. Pre + underprint in white + the contrast color yellow.

Screen printing printing method technically illuminated

SCREEN PRINTING MATERIAL

Many years of experience in screen printing, a wide range of raw materials, ensures the optimal selection of the appropriate textile to achieve a perfect printing result. Therefore, at the beginning of an order, we carefully select the appropriate raw material. We offer both inexpensive and high quality textiles. The higher the quality of the material, the better the printing result: materials with high quality have fine mesh and so fine details can be better reproduced on them.

SCREEN PRINTING COLOR

Our colors are carefully selected before screen printing, matched to the textile and incorporated in the best possible way to guarantee a comfortable wear on the textiles. We use both water-based pigment inks and plastisol inks. In order to achieve a pleasant feel even on dark textiles, we print with etching inks (Discharge), which remove the color from the fabric. The color-fast reproduction plays a big role on which we attach great importance. Plastisol inks and pigment inks can be mixed and printed according to solid colors such as Pantone® color values.

COLOUR ACCURACY IN SCREEN PRINTING

In the screen printing process it is possible to achieve a very nice color accuracy. The ink can be mixed to match your desired solid colors according to Pantone, HKS, RAL or CMYK.

OVERVIEW OF DIFFERENT SCREEN PRINTING COLORS

WHITE PLASTIC AND WATERCOLOR

Printing white on dark textiles is possible with various ink systems. These include water-based inks and solvent-based plastisol inks. However, the opacity of the color is always important, which is adapted to the design in the given cases. Through the opacity you also have the possibility to achieve certain effects and to design the textile in the best possible way. In this overview we illustrate different possibilities in terms of opacity.

COLOURED PLASTISOL AND WATER-BASED PAINT

To perfectly implement a colored coverage on a dark textile, this works as with pure white printing. Either with an underprint or with a multiple print. You can also control the opacity and achieve certain effects with a small amount of ink. To get a perfect result in the interaction of haptics and coverage, a mixture of etching and regular screen printing is recommended.

DARK PLASTISOL & WATERCOLOUR

Black or coloured printing on light textiles is far less problematic than on dark garments. On light fabrics you have full coverage and there is no need to underprint. This influences the colour application and you get a very fine feel. If desired, a raised layer can be applied to the textile with the appropriate additives to achieve a raised effect.

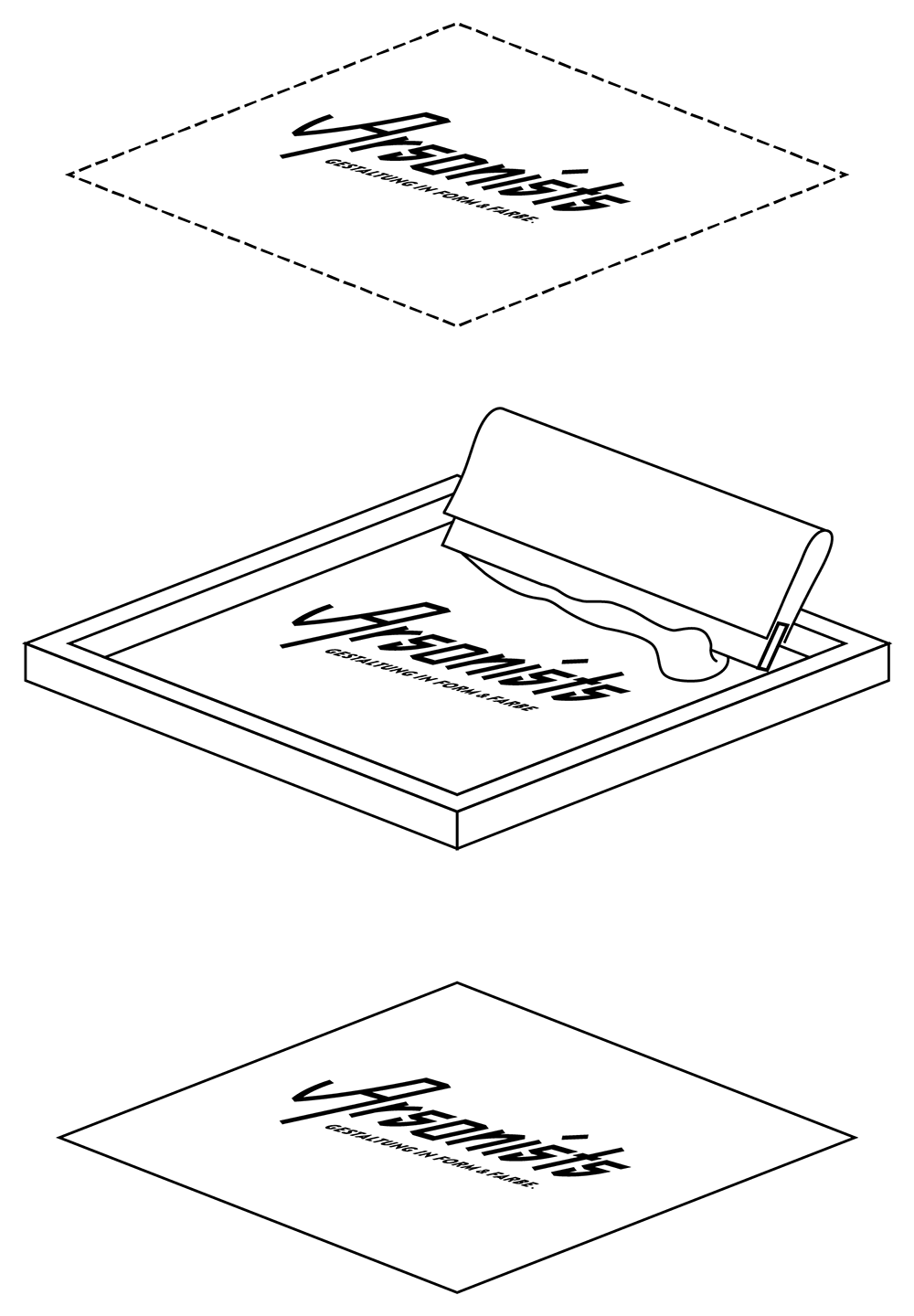

SCREEN PRINTING - THIS IS HOW IT WORKS

The screens are exposed with your motif and a screen printing stencil is created on the fabric. In those places of the fabric where no color is to be printed according to the print image, the mesh openings of the fabric are made impermeable to color by a stencil. After creating the frame, we brace the screen printing frames in a so-called carousel and perfectly match all the individual colors and surfaces to each other. Now the color is pressed through the screen with a screen printing squeegee and fixed on the textile by means of a continuous dryer or intermediate dryer in the case of multi-color screen printing and thus made durable.

Screen printing in detail

Development slide

black areas are not exposed on the screen

Screen printing squeegee

Tool that pushes the paint through the screen

used color

is printed through the screen onto the textile

Screen printing frame

unexposed areas are washed out of the light-sensitive layer, thus creating a "stencil" with which the motif can be printed

Textile material

is printed with corresponding color

SCREEN PRINTING IRIS PRINTING PROCESS

Through years of experience in screen printing, our team masters a variety of different printing techniques. Iris printing is here a special type of screen printing and always ensures a visually impressive result through many colors. By mixing the colors directly on the screen itself, it is also possible to create single or multi-colored color gradients in the screen printing process. Our printers are specialists in iris printing and will realize your color gradients with the highest precision with the rubber squeegee.

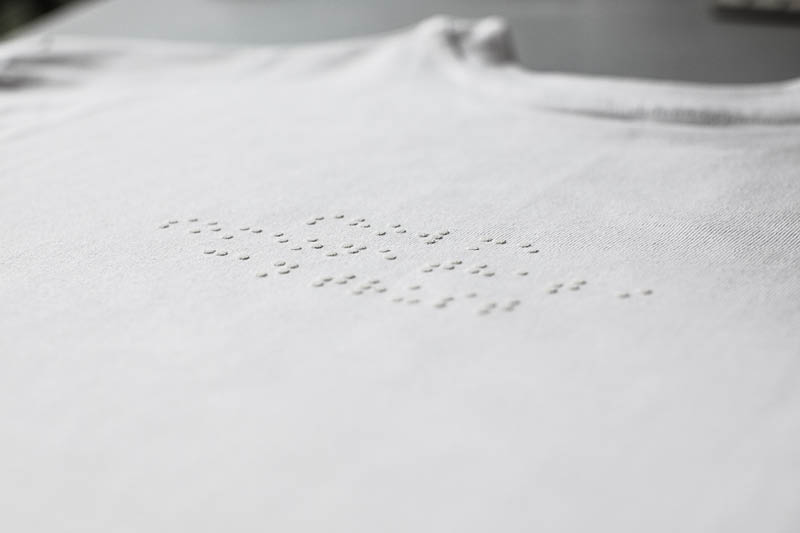

RAISED 3D SILKSCREEN

With additives, a 3D effect can be achieved in screen printing that is raised on the textile. We are your partner when it comes to difficult to implement screen printing.

Relief printed by screen printing on a fine mesh shirt.

Raised prints on a 350g sweater fabric.

EFFECT COLORS IN SCREEN PRINTING

Screen printing is characterized by excellent color reproduction. In addition, there are also various effect colors that can be applied over the entire surface. We are happy to coordinate the right technique.

Flurescent colors printed by screen printing. Here in the view in daylight.

Flurescent colors printed by screen printing. Here without daylight.

Braille on shirt implemented with screen printing.

Special 3D printing for rubberized surface on thin technical substrate.

TONE ON TONE COLOR BY SCREEN PRINTING

Screen printing is perfect to bring tone-on-tone prints on textiles. Screen printing convinces not only by quality and wash resistance on all materials, but also with the largest color spectrum that can be brought to the fabric. The prerequisite for a perfect print result are solid prints.

Black screen printing on dark gray textiles

Black 3D Puff print on black textile

SCREEN PRINTING ON PAPER AND OTHER MATERIALS

In addition to screen printing on textiles, we also offer printing on paper at the highest level. Screen printing is used here on posters, art prints, packaging, business cards, greeting cards or other flat printable materials such as plates made of metal, wood, glass, ceramics or individual advertising materials.

FAQ around the topic screen printing

How does ink actually get through the screen in screen printing?

In screen printing, ink is printed with the help of a squeegee through a fabric that is clamped in a screen printing frame. Screen printing is a printing process that can be printed manually or automatically.

Do you also offer screen printing workshops ?

Yes, of course, we offer workshops for individuals on weekends, but also with pre-registration for your entire company. Here you can find more information about our screen printing workshops. Register now for a participation.

Screen printing on textiles - Is screen printing actually the right technology for me as a customer ?

We select the right finishing technique depending on your printing specifications. If screen printing is not the right technique due to the print run or many printing inks, we will be happy to recommend you all other offers appropriate to the number of pieces and printing process.

What are the advantages of embroidery compared to screen printing ?

In general, one of the main differences between embroidery and screen printing is the feel and look. Wash resistance is consistent with both printing methods and similar effects can be achieved. Feel free to contact our team and we will find the optimal printing techniques.

Screen Printing VS Digital Printing ?

Screen printing is always best for larger print runs, but if the print run is smaller or a print motif has a lot of printing colors, digital printing is more suitable. In screen printing, the process of setting up the machines is always very time-consuming and this is reflected in the price, especially in small runs. In digital printing, even small productions from 10 pieces are conceivable.

Where is your TEXTILE PRINTING SHOP IN MUNICH?

Our screen printing workshop is located in directly Giesing. We have the complete production on site and a showroom with our textile assortment. By appointment, we will gladly present you T Shirts. Sweaters, accessories and countless other textiles.

Directions to the screen printing Arsonists ?

You are welcome to come by car, we have parking right in front of our location. Visit us from home with Munich's public transport, get off at Silberhornstraße. From here it's only a few minutes walk to our screen printing workshop.

How long are the delivery times usually ?

Usually we have a delivery time of 5-10 business days after order approval. But we also offer express models within 3 or 5 business days. Please contact us for more information or click here directly.